√完了しました! 6061 aluminum stress strain curve 671373-6061-t6 stress strain curve

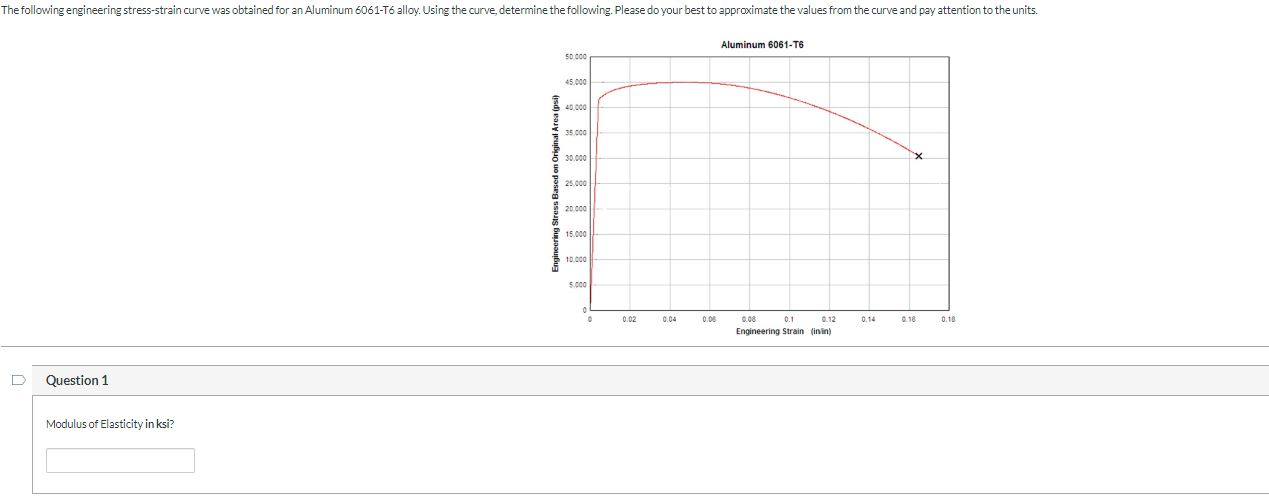

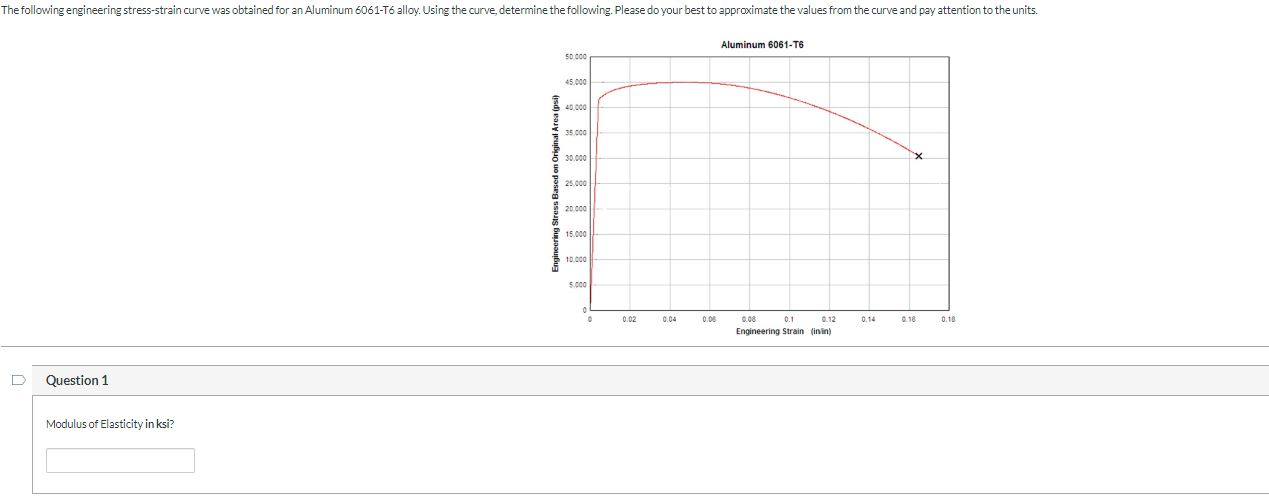

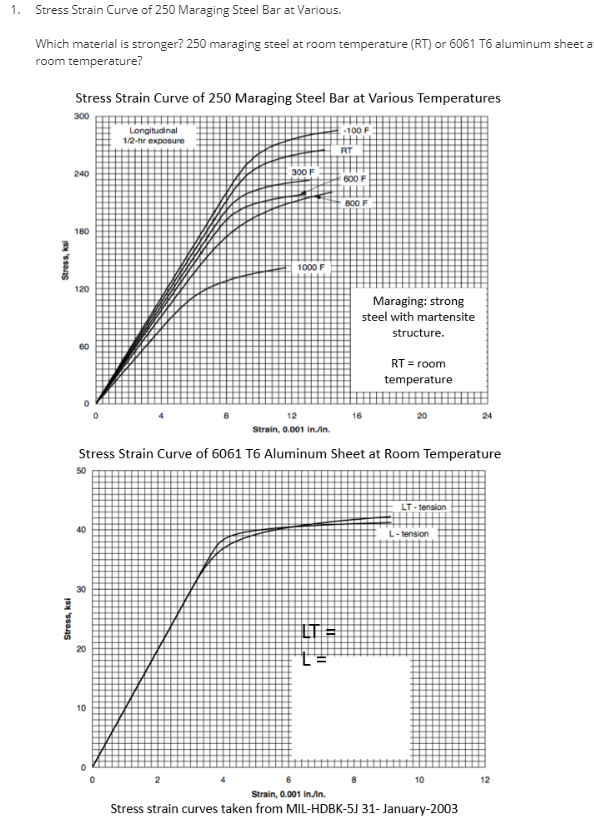

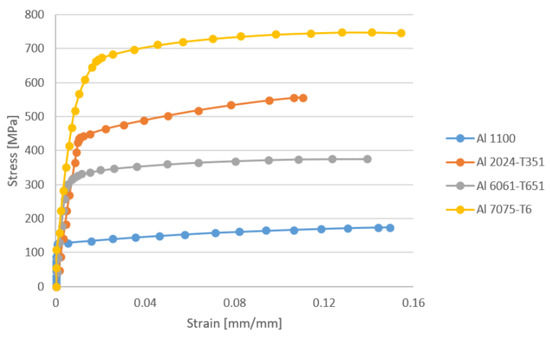

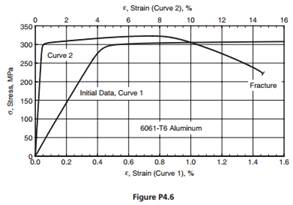

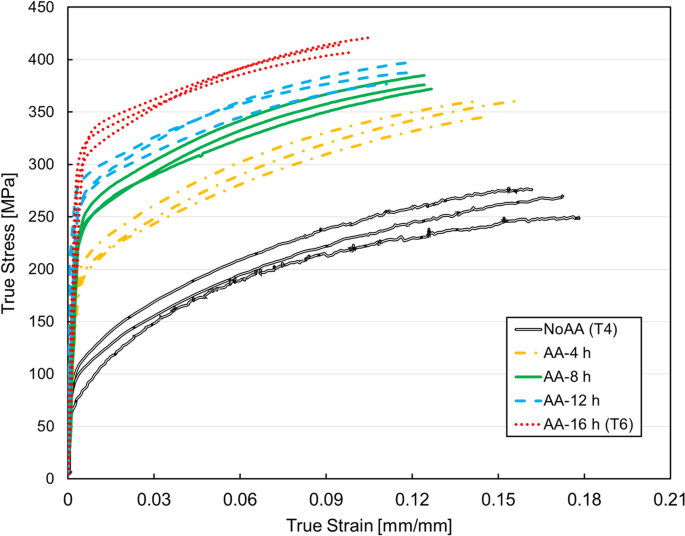

It turns out that we can get the energy of elasticity by taking the area under the curve of the stressstrain curve That area has been highlighted in the figure below, which is the area under the curve from the origin to the yield strength Energy of elasticity shown under the curve of the stressstrain curveThe stressstrain curve and a straight line with slope of E and beginning at 0002 (02%) on the strain axis The most satisfactory definition of yield strength for aluminum alloys and many other materials Note At this definition of yield, the plastic portion of the strain is 0002 and the elastic portion of the strain is σ y σ σ y E E 124 Aging characteristic of 6061 aluminum sheet alloys at room temperature, 0°C (32°F) and 18°C (0°F) 14 25 Hardness variation with Time in T4 treatment 16 45 True stressstrain curve 34 46 The true stress versus the true strain, along with the

The Following Engineering Stress Strain Curve Was Chegg Com

6061-t6 stress strain curve

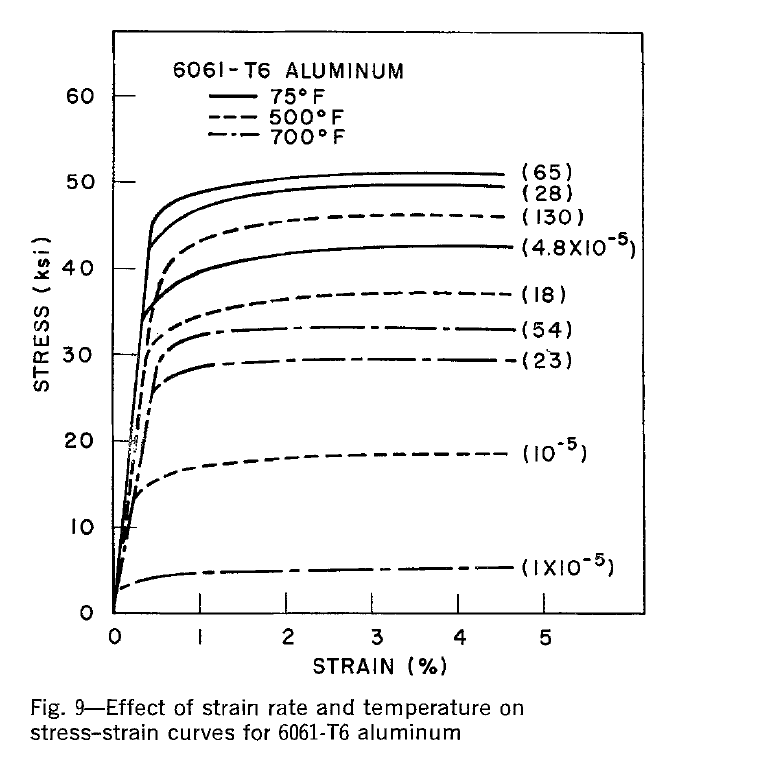

6061-t6 stress strain curve-Choice of pure aluminium as base material was justified by both the low yield strength and high ductility that it able to be offered In fact the proposed alloy is characterised by a very low strength (conventional 02% strain rate stress equal to about to 18 MPa after heat treatment), high hardening, large ductility and low specific weightJul 04, 19 · Description This dataset contains engineering stressengineering strain curves for aluminum 6061T651 test specimens prepared from bars of material from 9 lots available commercially Multiple specimens from each lot were tested in steadystate tension at 6 different temperatures (ie, the temperature was maintained constant through the test) under uniaxial and plane strain tension stress

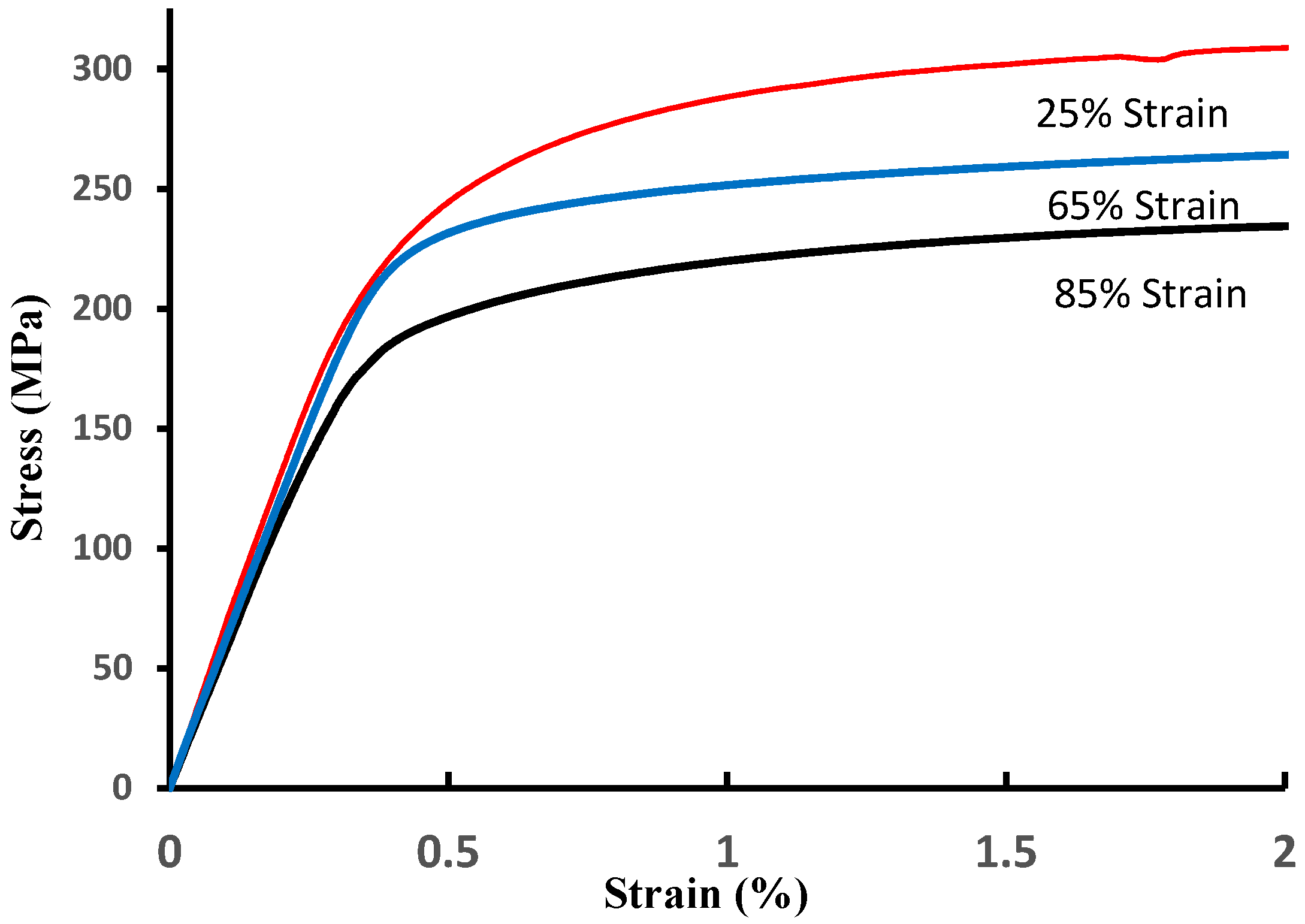

Fitting Stress Strain Curves Of 6061 Aluminum Alloy Under Different Download Scientific Diagram

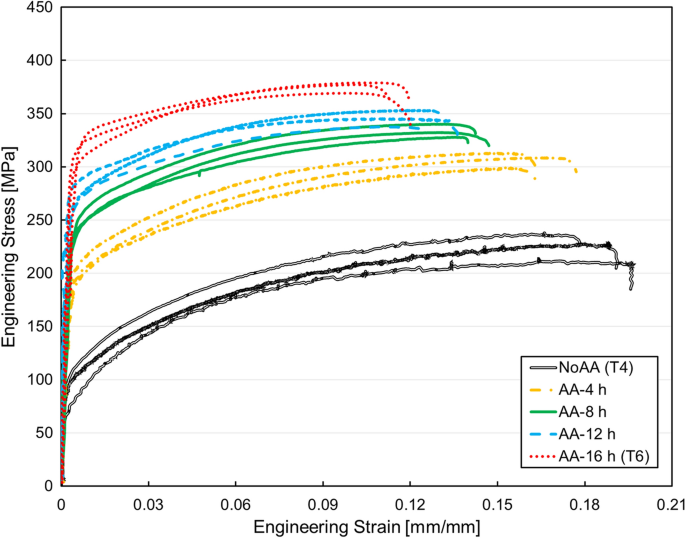

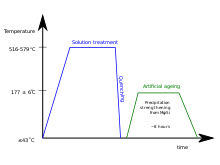

6061 Aluminium Aging 6061 aluminium alloy sheets, plates, rolled or coldrolled wire, rods, bars, and drawn tubing are aged to a metal temperature of 160 °C (3 °F) and maintaining it for 18h Extruded rods, rods, shapes and tubes;Sep 22, 12 · from asreceived and heat treated 6061 aluminum alloy were studied (Marini & Ismail, 11) and, it is conclude that the SN curve shows that heat treated T6 alloy exhibit higher fatigue life andState parameter based modelling of stressstrain curves in aluminium alloys carried out for the purpose of obtaining the degree of Doctor technicae (Dr techn), submitted at TU Wien, Faculty of Mechanical and Industrial Engineering, by DiplIng Johannes Franz KREYCA MatNr under the supervision of

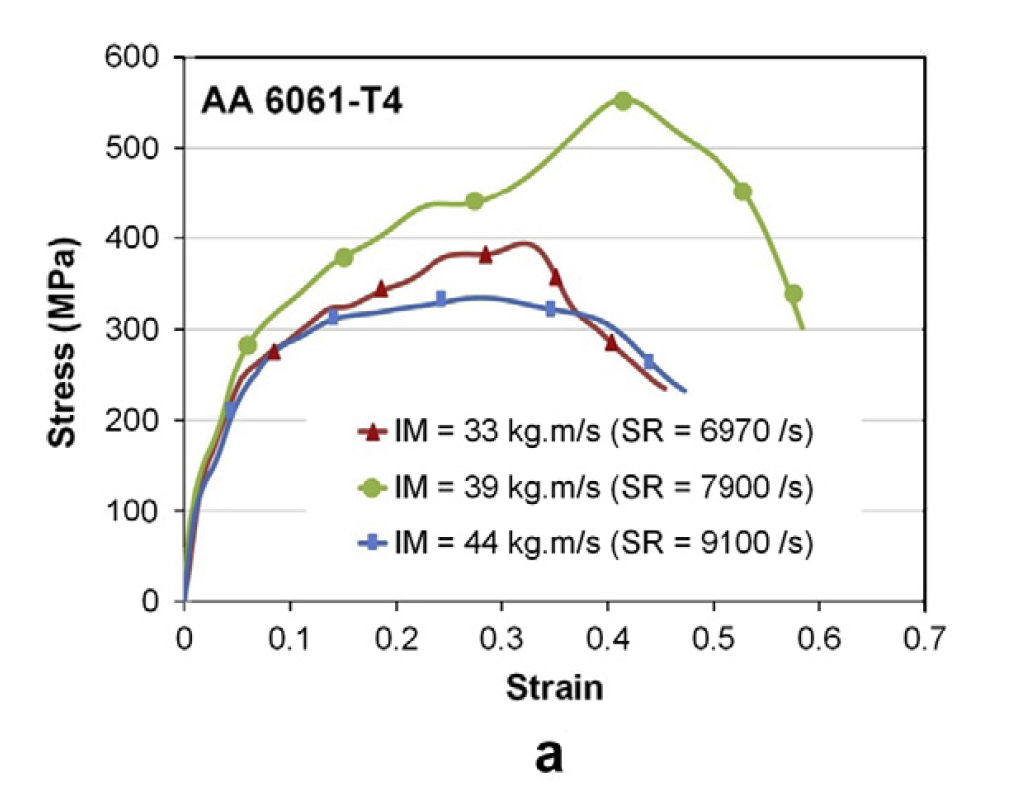

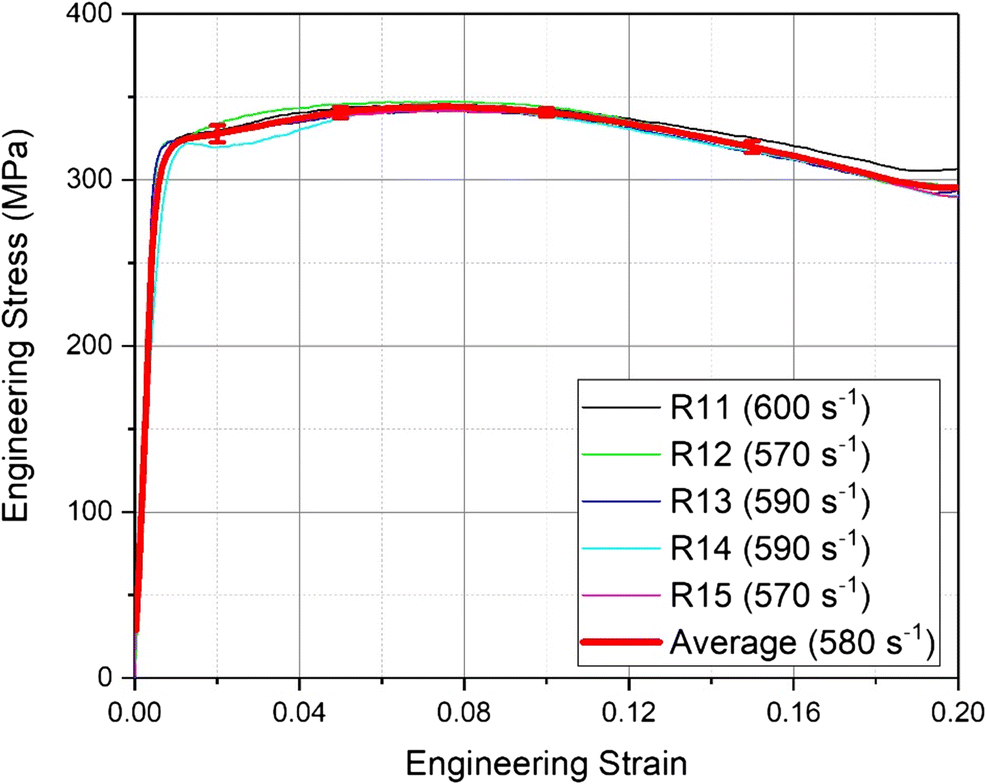

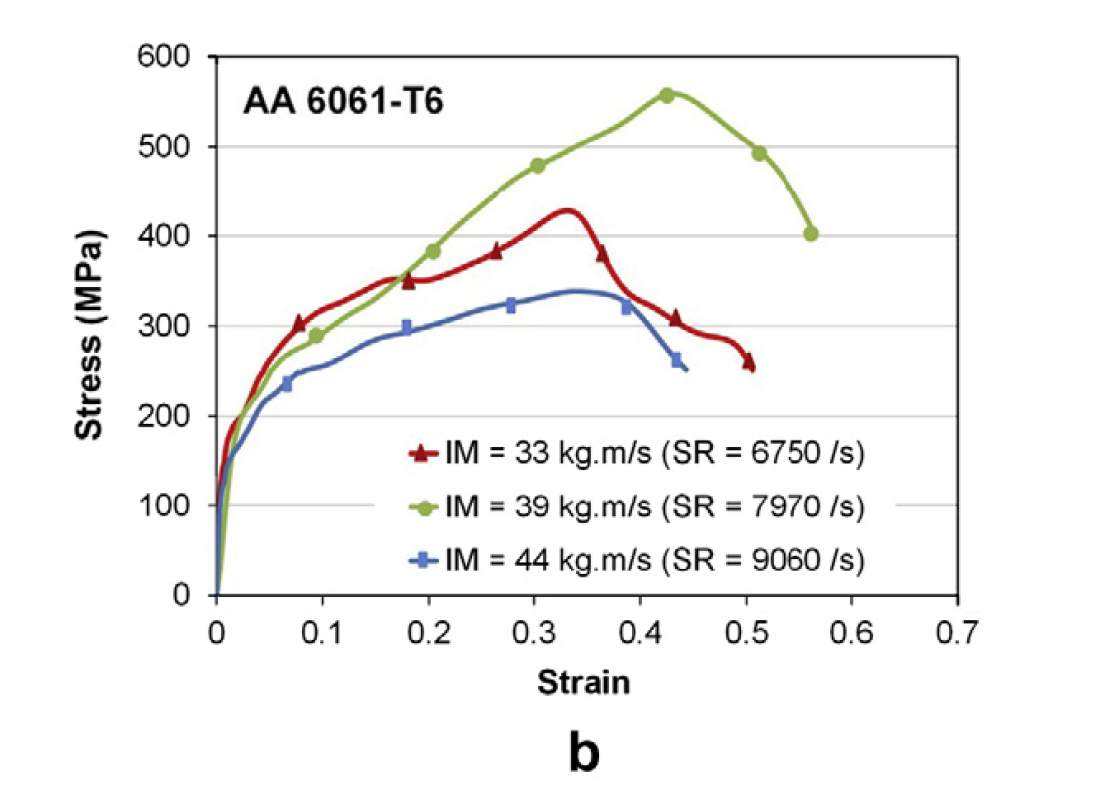

A very localized zone arrives to level of 106 s1The main objective of this work is the improvement in the Al 6061 T6 alloy characterization starting from compression experimental data in order to obtain moreResulting temper is 6061T6 Designing Aluminum Structures 34 Heat Treatment Tempers T1 through T4 naturally aged (6005T1) T5 through T9 artificially aged (6063T6) Artificial aging makes the stressstrain curve flatter after yield, which affects the inelastic buckling strengthFig 3 Comparison between monotonic and cyclic stressstrain curve for asreceived 6061 aluminium alloy Fig 4 Comparison between monotonic and cyclic stressstrain curve heat treated 6061T6 aluminium alloy Table 3 Cyclic stressplastic strain parameters for asreceived 6061 aluminium alloy 6061 Al Alloy Asreceived T6

The mechanical properties of two aluminum alloys and a fuel dispersion have been investigated for the purpose of selecting a cladding material and supplying data for design evaluation of the Advanced Test Reactor fuel plates The properties of the X8001, 6061, and the U/sub 3/O/sub 8/Jul 02, 21 · The mechanical properties of 6061 aluminum alloy differ based on how it is heat treated, or madeAbstract Recent spherical microindentation stressstrain protocols were developed and validated on Al6061 (DOI /s) The scaling factor between the uniaxial yield strength and the indentation yield strength was determined to be about 19 The microindentation stressstrain protocols were then applied to a microstructurally graded sample in an effort to

Effective Stress Strain Curves Of 6061 T6 Aluminum Alloy Tested In The Download Scientific Diagram

Engineering Stress Strain Data From Tensile Test On Chegg Com

These curves are proposed and presented for sagtension calculations only Stress Strain Curves are not a useful parameter for product acceptance The study has been completed for the following types of bare stranded conductors ACSR (Al/Steel strands) 5005 Aluminum Alloy (Strands) 7, 19, 37 & 61 61 Aluminum Alloy (Strands) 7&19 37 & 61 6/1 7/1Figure 7 The effect of stress ratio, R, on Wöhler curves in axial fatigue results of 6061T6 aluminum alloy 29 9 Figure 8 Fatigue crack initiating pore near surface of a 319 aluminum alloy casting 37Typical at 77°F Melting Point 5 6517 °C 1080 15 °F AA;

Scielo Brasil Effects Of Processing Parameters On Microstructure And Mechanical Properties Of Powder Thixoforged Sic B Sub P Sub B 6061 Al Composite Effects Of Processing Parameters On Microstructure And Mechanical Properties Of Powder

A Bar Of A 6061 Aluminum That Exhibits The Chegg Com

However, the failure strain remains relatively constant from roomtemperature to 400°C Above 400°C, the failure strain increases significantly@article{osti_, title = {Comparison of flow curves of 6061 aluminum alloy at high and low strain rates}, author = {Carden, A E and Williams, P E and Karpp, R R}, abstractNote = {Low strainrate tensile test data (10/sup 5/ to 10/sup 2/ s/sup 1/) were obtained for 6061 aluminum alloy in the T6 and 0 condition Little, if any, strainrate effect was observed over this range of6000 Series Aluminum Alloy Material Notes Information provided by Alcoa and the references General 6061 characteristics and uses Excellent joining characteristics, good acceptance of applied coatings

Estimation Of Ultimate Strength In Single Shear Bolted Connections With Aluminum Alloys 6061 T6 Sciencedirect

1

WA001 Heattreatable aluminum alloys, true stressstrain curves XT6, 14T4, 24T36, 24T86, 6061O, 6061T4, 6061T6, 6063T6, 7075O, 7075T6, 7079T6, 7178T6 WA002 1060O aluminum alloy rod, tensile stressstrain curves The upper row of strain values on the abscissa applies to both the complete true curve and the completeIdentifying the stress–strain curve of materials by microimpact testing Application on pure copper, pure iron, and aluminum alloy 6061T651 Volume 30 Issue 14A material of strain hardening Fig (1a) shows stress strain curve of aluminum alloy 6061T6 obtained from simple tension test of standard tensile test specimen 1 Fig (2b) illustrates flow curve extracted from stress strain curve of Fig (1a) The constitutive equations of the proposed model are based on hook law for elastic

Iopscience Iop Org Article 10 10 1742 6596 1198 3 0302 Pdf

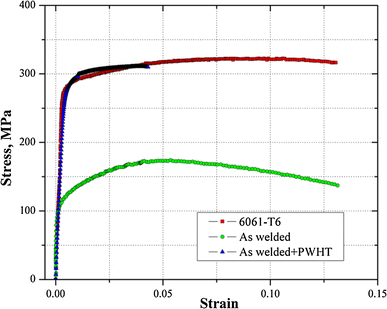

Figure 9 Recovery Of Mechanical Properties Of A 6061 T6 Aluminum Weld By Heat Treatment After Welding Springerlink

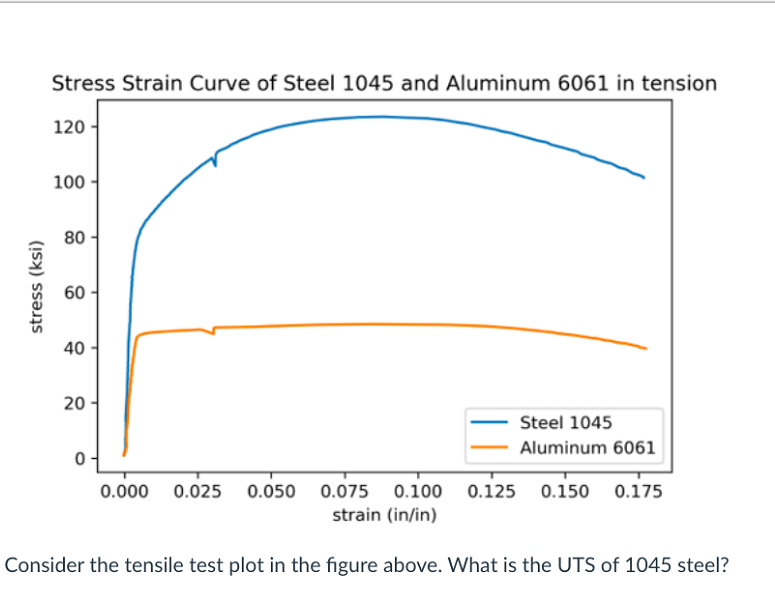

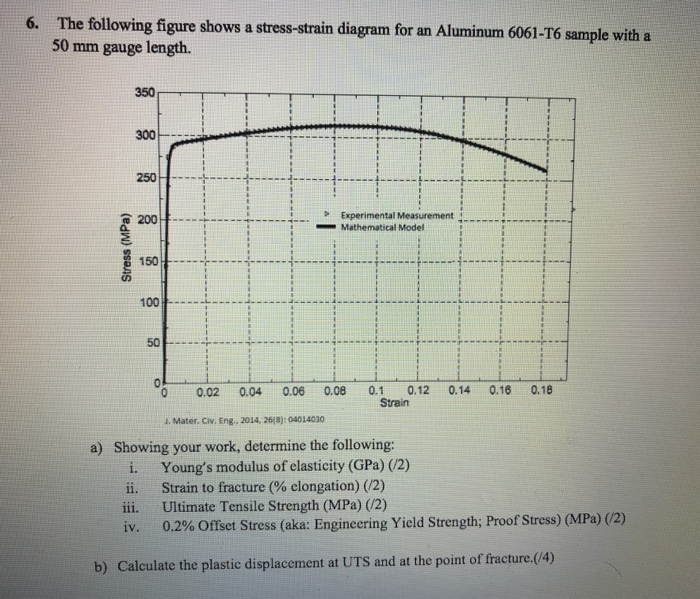

Apr 13, 16 · Figure 9 shows the SN curves of AA 6061T6 butt joints processed by TIG welding and VB and the recommended design curves in three specifications The recommended design curves of IIW FAT 45 and Eurocode 9 category 567 had been multiplied by 13 in Figure 9 The stress amplitude in the fatigue experiments was 40%–85% of the tensile strengthFigure 13 Engineering Stress vs Engineering Strain curve for heat treated Aluminum 6061, highlighting U) and the fracture strength f) By using equation 3 the method of 02% offset the proportional limit, yield strength, and Elastic modulus were calculated by using the elastic regions of the engineering stressstrain curves for Aluminum6061 and heat treated Aluminum 6061Feb 10, 16 · 6061 Aluminum Figure 13 Engineering Stress vs Strain plot for Aluminum Specimen Ductility 6061 Aluminum exhibits a large region of plastic deformation before fracture which is indicative of ductility

Full Range Stress Strain Curves For Aluminum Alloys Journal Of Structural Engineering Vol 147 No 6

Stress Strain Properties Of Artificially Aged 6061 Al Alloy Experiments And Modeling Springerlink

Therefore, there exists the need to have adequate testing methods to obtain stress strain data at high temperatures Plane strain compression tests at elevated temperatures using aluminum alloy 6061 as a testing material were performed using the Gleeble 1500 Thermomechanical simulatorAnd 75ST6 aluminum alloys are presented as S N curves and stress range diagrams to illustrate and analyze the effects of (a) stress ratios in the range from static tension to reversed axial stress, (b) stress magnitudeFatigue behaviour of an artificial aged powder metallurgy 6061 aluminium alloy, and a composite made of this alloy with 15% volume fraction of SiCp was investigated The stress and strain, much of this research has focused on the advanced materials particulate ceramic reinforced metal matrix composites (PMMCs)

The Following Engineering Stress Strain Curve Was Chegg Com

Aluminum 6061 T6 Scatter Chart Made By Harr1961 Plotly

The accompanying graph shows the results on the specimen as Stress (YAxis) versus Strain (XAxis) We can verify this curve empirically by setting up a simple test using an MTII/Fullam SEMTester 100 Tensile Stage Unit with a standard "Dog Bone" style specimen made out of 6061 T6 aluminum, having a reduced center section (5 mm wide by 16Jul 02, 21 · They are calculated from the elastic regions of stressstrain curves (read more on this topic in our article all about 3003 aluminum alloy), and are good indicators of general material strength For 6063 aluminum, its modulus of elasticity and shear modulus are 6 GPa (10,000 ksi) and 258 GPa (3,740 ksi), respectivelyFigure 1 Stressstrain curve for Aluminum 6061T6 with the elastic and inelastic sections separated Figure 2 Stressstrain curve for Aluminum 6061T6 with the elastic section magnified 4 Figure 3 Stressstrain curve for 70/30 brass with the elastic and inelastic sections separated

True Stress Strain Vs Engineering Stress Strain Materials Science Engineering

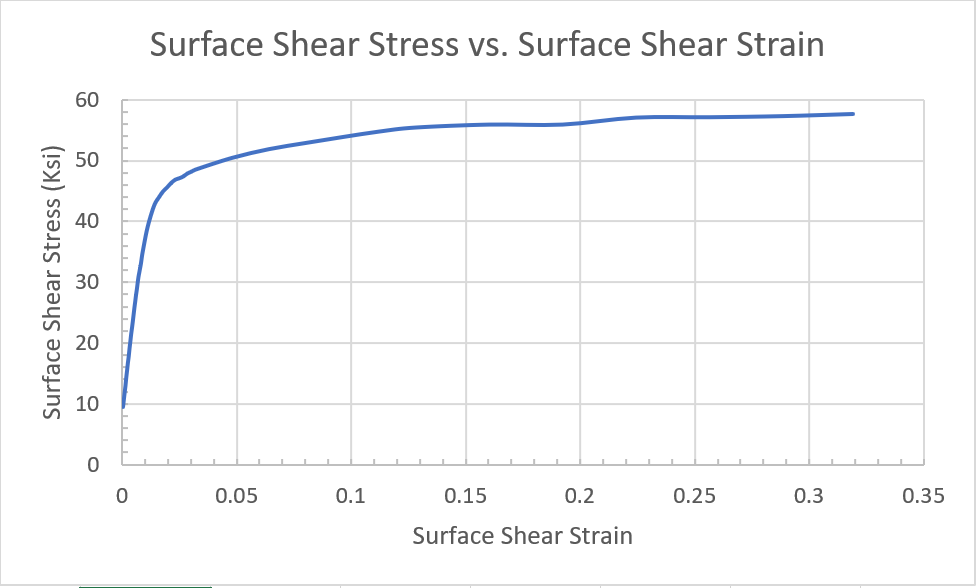

Find The Modulus Of Rigidity Using The Initial Chegg Com

2 The 6061T651 aluminium alloy This research was conducted on an AlMgSi aluminium alloy the 6061T651 aluminium alloy The 6061T651 alloy is a precipitation hardening aluminium alloy, containing Magnesium and Silicon as its major alloying elements The T651 treatment corresponds to stressrelieved stretch and artificially agingTypical range based on typical composition for wrought products >= 1/4 in thickness Eutectic melting can be eliminated by homogenization SolidusAluminum 6061O Categories Metal;

Www Sciencedirect Com Science Article Pii S Pdf Md5 c6a5c8a8fa57a53b191ed8 Pid 1 S2 0 S Main Pdf

Universal Stress Strain Equation For Metallic Materials Journal Of Materials In Civil Engineering Vol 26 No 8

Graph 1 – Stress vs Strain for Untreated Al 6061 Alloy Discussion The values that are given theoretically have the big difference between the text book values and the values that have obtained by the experiment In the textbook the value given is 10 x 10^6, but through the experiment the value get is (61 01) x 10 6Data is available here (registration required for download)http//forumsmbarkeycom/indexphp?topic=1460Jul 31, · Ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 290 MPa The ultimate tensile strength is the maximum on the engineering stressstrain curve This corresponds to the maximum stress that can be sustained by a structure in tension Ultimate tensile strength is often

Stress Strain Curves Of 6061 T6 And 6063 T5 Download Scientific Diagram

1 Stress Strain Curve Of 250 Maraging Steel Bar At Chegg Com

The experimental database includes over 700 engineering stressstrain curves obtained from 56 sources and covers five common aluminum alloy grades, namely 5052H36,6061Aug 01, 19 · Abstract Stressstrain curves in steadystate tension of aluminum 6061T651 sourced from 9 lots of material from several manufacturers at 6 temperatures (,100,150,0,250,300 °C) are presented A total of 100 stressstrain curves for uniaxial tension specimens and 54 stressstrain curves for plane strain tension specimens are shared6061T6 cyclically hardens a small amount at room temperature typically 241 MPa (35 ksi) to 262 MPa (38 ksi) At 149OC (300OF) it cyclically softens at total strain ranges below about two percent and cyclically hardens at higher total strain ranges Because 6061T6 aluminum cyclically hardens, a value of 262 MPa (38 ksi) was used for

Young S Modulus Of Al Physics Forums

Stress Strain Curves A Cast Aluminum B 6061 T6 Aluminum Alloy Download Scientific Diagram

Fig 2 Planestrain fracture toughness as a function of material tensile yield strength Comparison of several 00 and 7000 series aluminum alloys Source Ref 1 Fig 3 Planestrain fracture toughness for 254 to 381 mm (1 to 15 in) thick commercial aluminumalloys Source Ref 6 Fig 4 Planestress fracture toughness for 1Calculated stressstrain curve Finally, given the magnitude of the uniform elongation, it would be straightforward to calculate the ultimate tensile stress if desired 3 Results and Discussion Figure 1 and 2 compare the results for the experimental and model predictions for stressstrain curves for the underaged and overaged samplesJun 06, 21 · The experimental database includes over 700 engineering stress–strain curves obtained from 56 sources and covers five common aluminum alloy grades 5052H36, 6061T6, 6063T5, 60T6, and 7A04T6 The developed model is shown to be more accurate in predicting the fullrange stress–strain response of aluminum alloys than existing

Dynamic Experimental Studies Of A6n01s T5 Aluminum Alloy Material And Structure For High Speed Train

Cyberleninka Org Article N Pdf

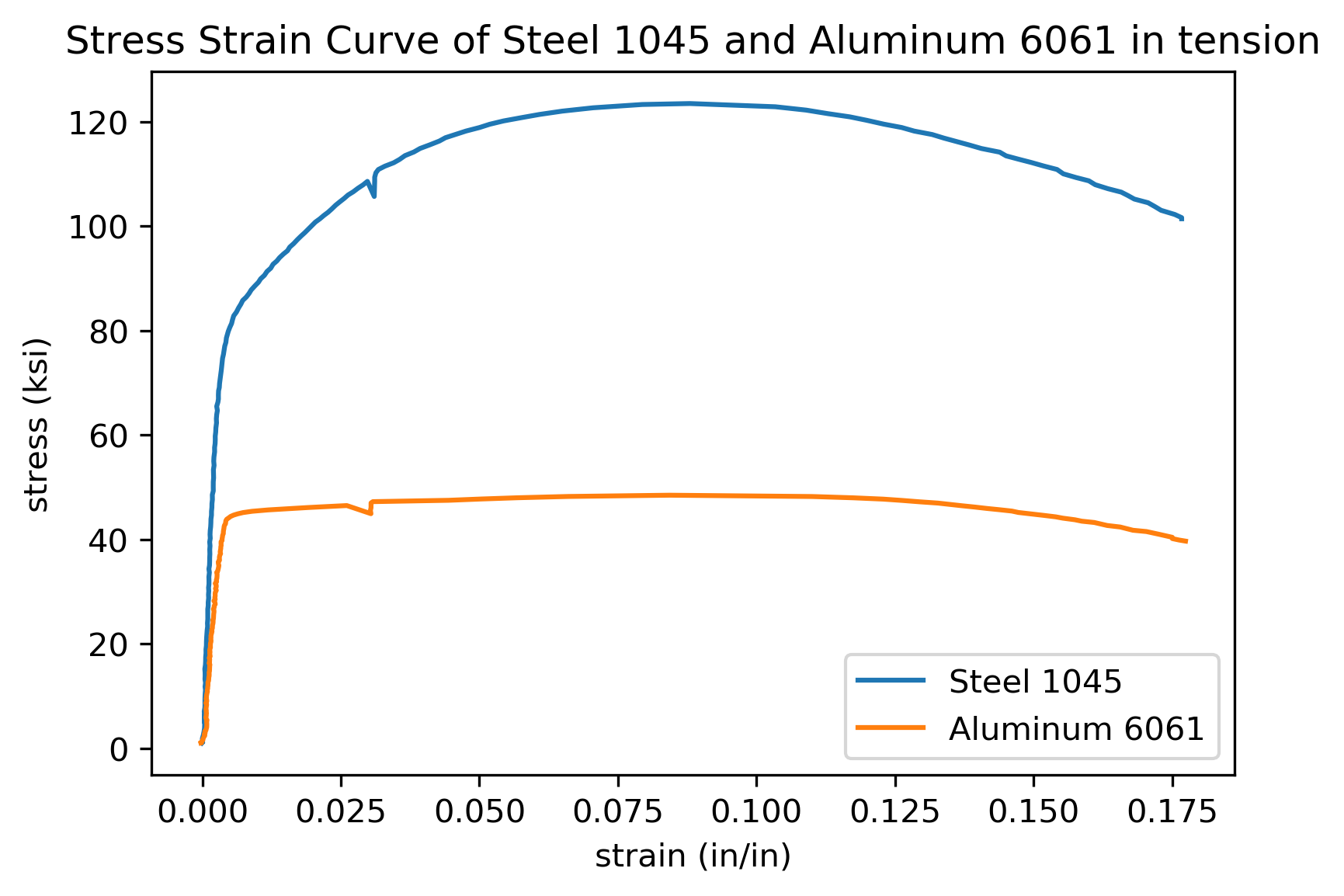

Dies and hand forgings, rolled rings are aged to a metal temperature of 175 °C (345 °F) and held for 8 hoursStress (psi) Strain (in/in) Complete Tensile Stress‐Strain Curves Steel and Aluminum Steel ‐common structural steel Aluminum ‐6061 alloy Tested in Lafayette College Materials Laboratory (average of 2 tests, each) Steel Aluminum 51,000 psi 42,873 psi SUMMARY (3 digits) Steel UltimateStrength 51,000 psiApr 28, 15 · Elevated temperature 6061T651 engineering stressstrain relations are shown in Figure 6 The measured mechanical behavior is similar to that for 50H116;

Http Www Ccsenet Org Journal Index Php Jmsr Article Download 691

Www Matec Conferences Org Articles Matecconf Pdf 16 22 Matecconf Icfst16 Pdf

Sep 25, 13 · stressstrain curve's linear elastic regime U el max = σ yε y (5) Where σ y and ε y are the yield stress and yield strain at which linear elastic behavior ceases At larger strains, material deformation becomes irrecoverable and nonlinear, or plastic Along with σ y and ε yJan 01, 11 · In Figure 1 strain rate behaviour during bullet inlet phase is shown A localized area reaches strain rate value that exceedes 103 s1;Ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 290 MPa The ultimate tensile strength is the maximum on the engineering stressstrain curve This corresponds to the maximum stress that can be sustained by a structure in tension Ultimate tensile strength is often shortened to "tensile strength" or even

Hoge

Fitting Stress Strain Curves Of 6061 Aluminum Alloy Under Different Download Scientific Diagram

Elongation (in 508 mm, or 2 in), 427% Reduction of area, 91% True strain at maximum load, 248% A log log plot of the stressstrain curve would yield a slope (n) of 022 in the area of uniform plastic deformation UNS 1060 Source Alcoa, Aluminum Research Laboratory, New Kensington, PA, Oct 1951Aluminium alloy (AA 6061) The figure 4 shows that the Stress and Strain curve for Aluminium alloy under the compression test Fig5 Stress and strain curve The figure 5 shows that the Yield strength calculation by offset method by 02% of gauge length In this test the specimen dimensions are 30mm gauge length and mm diameter

Coatings Free Full Text Stress Corrosion Cracking Resistance Of Cold Sprayed Al 6061 Deposits Using A Newly Developed Test Fixture Html

Metals Free Full Text Prediction Of The Bilinear Stress Strain Curve Of Aluminum Alloys Using Artificial Intelligence And Big Data

Stress Strain Curve Of 6061 Aluminum Alloy Download Scientific Diagram

Aluminum 6061 T6 Stress Strain Curve Aluminum 6061 Stress Strain Curve

Why Do We Use 0 2 Offset In Aluminum Stress Strain Curve Quora

Stress Strain Curve For Aluminium Alloy 7075 Download Scientific Diagram

6061 T6 Aluminum Yield Stress Search For A Good Cause

Xdocs Pl Doc Mechanical Behavior Of Precipitation Hardened Aluminum Alloys 48gev2w5n2

6061 Aluminium Alloy Wikipedia

1

Stress Strain Curve Of Steel 1045 And Aluminum 6061 Chegg Com

Describe Draw The Stress Strain Curve Of Aluminum Vs Steel On The Same Graph Mechanical Engineering Hardware Fyi

Dl Asminternational Org Handbooks Book Chapter Pdf A Pdf

Www Imechanica Org Files 1 S2 0 S Main Pdf

Stress Strain Curves Of Uniaxial Tensile Testing Of Al 6061 T6 At Download Scientific Diagram

Iopscience Iop Org Article 10 10 1742 6596 1198 3 0302 Pdf

Adesola

Universal Stress Strain Equation For Metallic Materials Journal Of Materials In Civil Engineering Vol 26 No 8

Full Range Stress Strain Curves For Aluminum Alloys Journal Of Structural Engineering Vol 147 No 6

Tests And Design Of Aluminum Alloy Compression Members Journal Of Structural Engineering Vol 132 No 7

Mechanics And Full Field Deformation Study Of The Ring Hoop Tension Test Sciencedirect

Stress Strain Curve Of Al 6061 T6 Download Scientific Diagram

Figure 3 From Effect Of Artificial Aging On Strength And Wear Behaviour Of Solutionized Aluminium 6061 Alloy Semantic Scholar

Stress Strain Curves A Cast Aluminum B 6061 T6 Aluminum Alloy Download Scientific Diagram

Www Matcalc At Images Stories Publications Phd Thesis Kreyca 17 Pdf

True Stress Strain Curves For 6061 T6 Plates Weld Metal Haz And As Download Scientific Diagram

True Stress Strain Curve Of Al 6061 Download Scientific Diagram

Http Www Ccsenet Org Journal Index Php Jmsr Article Download 691

Aem 648 3 6061 T6 Aluminum Alloy Stress Strain Curve Analysis Youtube

Plotting A Stress Strain Curve With Python And Matplotlib Python For Undergraduate Engineers

True Stress Strain Vs Engineering Stress Strain Materials Science Engineering

Figure 9 An Apparatus For Tensile Characterization Of Materials Within The Upper Intermediate Strain Rate Regime Springerlink

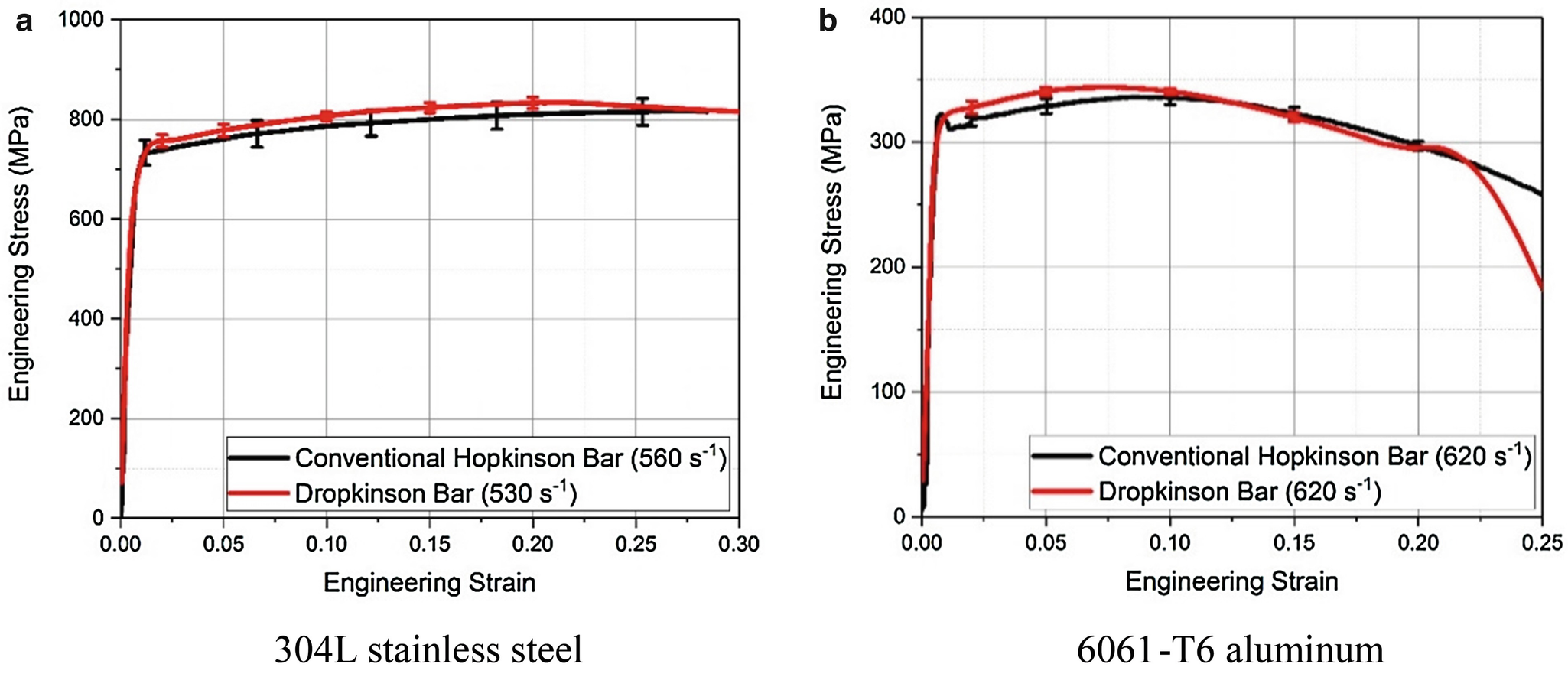

Development Of Dropkinson Bar For Intermediate Strain Rate Testing Springerlink

True Stress Strain Curve Of Al 6061 Download Scientific Diagram

Solved A Strain Rate Dependence Test Is Conducted On Samp Chegg Com

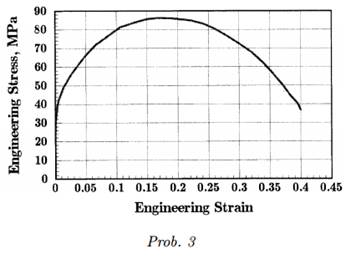

2 The Following Figure Shows The Stress Strain Chegg Com

Relationship Between Mechanical Properties And Microstructural Response Of 6061 T6 Aluminum Alloy Impacted At Elevated Temperatures Sciencedirect

1

Www European Aluminium Eu Media 1532 m Materials 2 Alloy Constitution Pdf

Www Mdpi Com 75 4701 8 7 528 Pdf

Would You Rather A 6061 Or 7075 Stem General Bmx Talk Bmx Forums Message Boards Vital Bmx

Tensile Test Of 6061 Aluminum Alloy Material Science Bohatala Com

True Stress Strain Vs Engineering Stress Strain Materials Science Engineering

Dl Asminternational Org Handbooks Book Chapter Pdf A Pdf

Dissipated Strain Energy Of Aluminum Alloy 6061 T6 Induced By Low Cycle Fatigue Semantic Scholar

Adesola

Solved The Figure Below Shows The Engineering Stress Strain Curve For 1 Answer Transtutors

Stress Strain Characteristics Of Aluminum Protocol

Figure 5 From Stress Analysis Of Switchover Module With Al6061 T6 And Al7075 T6 For Hybrid Locomotion Mobile Robot Semantic Scholar

Stress Strain Data For Aluminum 6061 T651 From 9 Lots At 6 Temperatures Under Uniaxial And Plane Strain Tension Abstract Europe Pmc

Stress Strain Characteristics Of Aluminum Protocol

Tensile Behaviour Of Aluminium 7017 Alloy At Various Temperatures And Strain Rates Sciencedirect

Www Matec Conferences Org Articles Matecconf Pdf 16 22 Matecconf Icfst16 Pdf

Stress Strain Curve For The 60 T6 Aluminium Alloy 1 Mm Thick Sheet Download Scientific Diagram

Measurement Of The Deformation Of Aluminum Alloys Under High Strain Rates Using High Speed Digital Cameras

Cyclic Stress Strain Behavior And Low Cycle Fatigue Life Of 6061 Aluminum Alloy Springerlink

The True Stress Strain Curve Of Al Alloy 5052 At Room Temperature From Download Scientific Diagram

Stress Strain Curves Of Aluminium Alloys 6061 T6 And 6063 T5 Download Scientific Diagram

Research Tue Nl Files Soyal Pdf

1

Solidmechs Blog General Properties Of Aluminum And Aluminum Alloys

Stress Strain Curves Of Aluminium Alloys 6061 T6 And 6063 T5 Download Scientific Diagram

Averaged Strain Energy Density Criterion To Predict Ductile Failure Of U Notched Al 6061 T6 Plates Under Mixed Mode Loading Sciencedirect

Stress Strain Curves Of 6061 T6 And 6063 T5 Download Scientific Diagram

Stress Strain Curve Of Aluminum 6061 T6 With Thickness Of 1 6 Mm Download Scientific Diagram

True Stress And Plastic Strain Data For Aluminum 6061 T6 And Uranium Download Scientific Diagram

Www Ijser Org Researchpaper Ductile Fracture Simulation Of Aluminum 6061 T6 Thin Sheet Pdf

Stress Strain Curve Of The As Received 7075 T6 Download Scientific Diagram

Solved Engineering Stress Strain Data From A Tension Test On 6061 T6 1 Answer Transtutors

Solved 6 The Following Figure Shows A Stress Strain Diag Chegg Com

Stress Strain Curves Of 6061 T6 And 6063 T5 Download Scientific Diagram

Www Jstor Org Stable

6 Stress Strain Curves Of Al 6061 T6 Aluminum Alloy For Various Strain Download Scientific Diagram

Stress Strain Properties Of Artificially Aged 6061 Al Alloy Experiments And Modeling Springerlink

Http Link Springer Com Content Pdf 10 1007 2f978 1 4613 3219 0 3 Pdf

Adesola

Http Www Ccsenet Org Journal Index Php Jmsr Article Download 691

Www Matcalc At Images Stories Publications Phd Thesis Kreyca 17 Pdf

コメント

コメントを投稿